Your Weekly Large Format Print Briefing [Week 49, 2025]

Your weekly 5-minute intelligence briefing for large format print professionals

This week was a snapshot of where the industry was quietly heading: hybrid water/UV chemistry winning awards, DTF software finally behaving like a serious production hub, prepress tools tightening quality control, real-world architectural graphics installs, and HP signalling how AI will reshape its workforce and strategy.

📢 This Week in Wide Format Brief

Fujifilm’s AQUAFUZE inkjet chemistry earned the RadTech Europe Innovation Award

Fiery’s Digital Factory 12 brought pro-grade colour and workflow tools to DTF printing

Sleek Signs used Drytac ReTac films to rethink a converted church space in Ottawa

Hybrid Software released PACKZ 11.5 with powerful new screening and 3D tools

HP announced workforce restructuring as part of an AI-driven transformation plan

📰 Top 5 Headlines This Week

Fujifilm AQUAFUZE Inkjet Chemistry Earned RadTech Europe Innovation Award

Summary:

Fujifilm’s AQUAFUZE inkjet technology won the RadTech Europe Innovation Award for its hybrid water-based/UV chemistry. The system delivered strong adhesion, high image quality and low-temperature LED curing without primers, while producing low-odour, non-hazardous prints suited for more sustainable wide-format workflows.

Takeaways:

Hybrid water/UV approach reduced reliance on primers and aggressive chemistries

LED low-temp curing opened doors for heat-sensitive substrates in wide format

Low-odour, non-hazardous prints supported ESG and operator-safety goals

Why It Matters:

AQUAFUZE pointed to a new class of inkjet chemistries that combined sustainability with practical performance. For wide-format providers, the prospect of primer-free adhesion, reduced odour and LED curing expanded media options and lowered compliance barriers in environments demanding cleaner production.

Digital Factory 12 Brought Professional-Grade Colour and Workflow to DTF Printing

Summary:

Fiery released Digital Factory 12, bringing pro-level colour control and workflow tools to DTF printing. The update included a new saturation rendering intent, integrated Fiery Color Profiler, and a built-in visual gang sheet builder. Improved markup tools aimed to reduce errors and streamline production across apparel and transfer workflows.

Takeaways:

Fiery colour engine and saturation rendering intent targeted apparel-grade consistency

Integrated Fiery Color Profiler enabled reproducible DTF output with in-house profiling

Built-in gang sheet layout reduced reliance on external apps and manual nesting

Why It Matters:

DTF grew faster than its software tools, and Digital Factory 12 helped close that gap. By pairing serious colour management with integrated gang sheet layout, Fiery gave shops a more stable, repeatable and less error-prone workflow—critical for scaling DTF beyond small-batch work.

Sleek Signs Used Drytac ReTac to Transform a Converted Church in Ottawa

Summary:

Sleek Signs used Drytac’s ReTac Clear PET and ReTac Textures Canvas films to transform a converted church in Ottawa into a modern sales centre. The removable films allowed window and wall graphics to be applied cleanly without damaging surfaces, showing how décor-grade materials can refresh sensitive architectural environments.

Takeaways:

ReTac films enabled removable, residue-free graphics for architectural interiors

Combining clear and textured films created cohesive multi-surface branding

Sales centres and real-estate environments remained high-margin décor opportunities

Why It Matters:

Applications like this highlight how film choice influences creative freedom and risk mitigation. Being able to specify removable films that work on both windows and walls gives PSPs confidence when pitching temporary or seasonal décor projects in high-value spaces.

Hybrid Software Released PACKZ 11.5 with New Tools for Labels and Packaging

Summary:

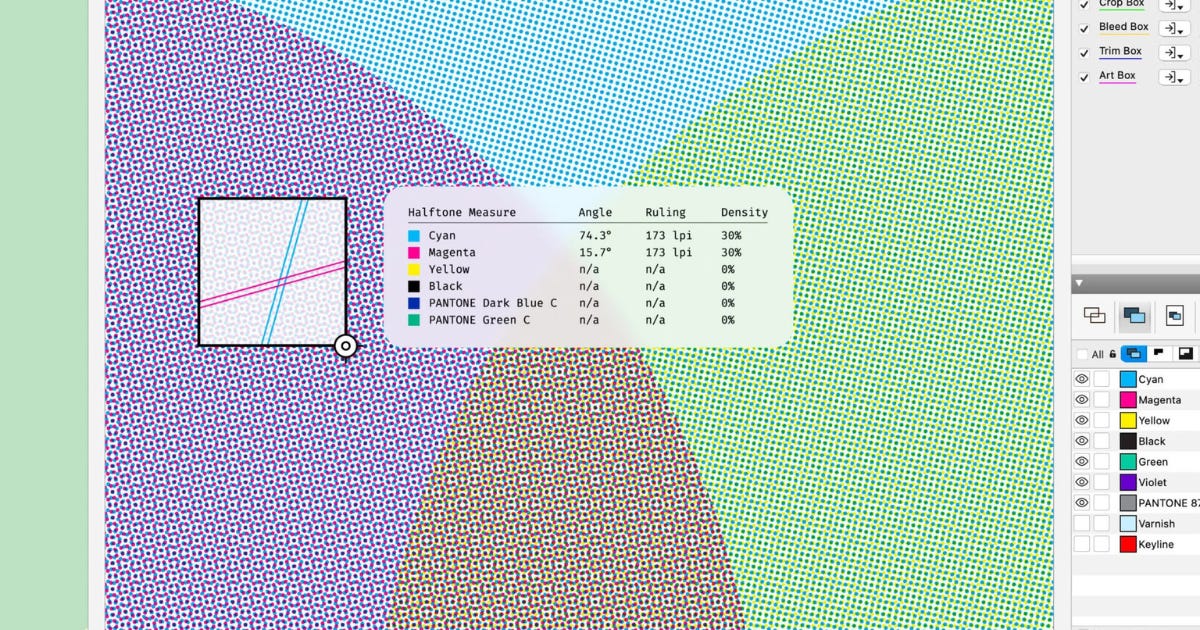

Hybrid Software introduced PACKZ 11.5 with new tools for packaging and label prepress. The release added a Halftone Detection Tool using Harlequin RIP data, extended CF2 3D variants for structural previews, improved spot-colour rendering and updated Laneplanner to align layouts with real press and finishing constraints.

Takeaways:

Halftone Detection Tool improved screening diagnostics pre-plate

CF2 3D variants streamlined design reviews and structural communication

Laneplanner reduced waste by respecting actual press limits and roll quantity constraints

Why It Matters:

Even though PACKZ targets packaging, the trend applies widely: prepress is becoming more production-aware. Better diagnostics and constraint-driven planning reduce surprises on press, tighten make-ready times and lower the cost of handling multi-SKU work.

HP Announced Workforce Restructuring as Part of AI-Driven Transformation

Summary:

HP announced workforce restructuring as part of a broader AI-driven transformation strategy, signalling a shift in priorities toward automation, software and data-centric services. While details were limited, the move suggested potential changes in how resources, development and support were allocated across HP’s print-related businesses.

Takeaways:

HP tied restructuring directly to AI and digital transformation initiatives

Signals possible redistribution of R&D and support resources across print vs. software

Indicates stronger push toward automation, analytics and predictive tools

Why It Matters:

OEM restructuring influences the tools print providers will rely on in the coming years. AI-oriented shifts affect product roadmaps, support models and investment priorities—critical context for shops planning hardware or workflow upgrades for 2026 and beyond.

🎯 This Week’s Strategic Takeaway

Across ink chemistry, RIP software, media applications and vendor strategy, one pattern stood out: the value shifted further from raw hardware speeds to smarter, lower-risk workflows. Hybrid inks targeted ESG goals, software upgrades strengthened production reliability, and AI-driven restructuring signaled where OEM investment was moving next.

❌ This Week’s Noise

This week didn’t bring much fluff, but even high-profile awards or restructuring headlines need context. Awards point to promising technology—not guaranteed readiness. Corporate news matters only when translated into real-world implications for support, product cycles and negotiation leverage.

📅 What’s Coming Up

🗓 FESPA Global Print Expo 2026 + Corrugated/Textile — 19–22 May 2026, Barcelona – Expect early sustainability-certified materials, next-gen hybrid systems, and new RIP automation modules targeting more connected workflows.

🔗FESPA Global Print Expo 2026

🧠 Smarter Every Week

When reviewing new software updates or RIP features, always run a baseline comparison job before rolling changes into full production. Print one controlled test file on your core substrates, measure colour drift, check screening integrity, and confirm finishing behaviour. A 10-minute test today prevents hours of troubleshooting later.

Conclusion

Thanks for tuning into this week’s Wide Format Brief! Remember to stay tuned for more industry news and insights to keep your business at the forefront of the printing world. Until next time, keep printing!