Your Weekly Large Format Print Briefing [Week 42, 2025]

Industrial corrugated enters the chat, color management takes center stage, and automation inches closer to lights-out. Canon unveils a heavy-hitting corrugated press, Epson debuts a strong-solvent-ready head, Kongsberg adds smart handling to reduce idle time, Techkon doubles down on G7 and shop-floor QC, and DuPont brings inks + Tyvek to the same stage.

📢 This Week in Wide Format Brief

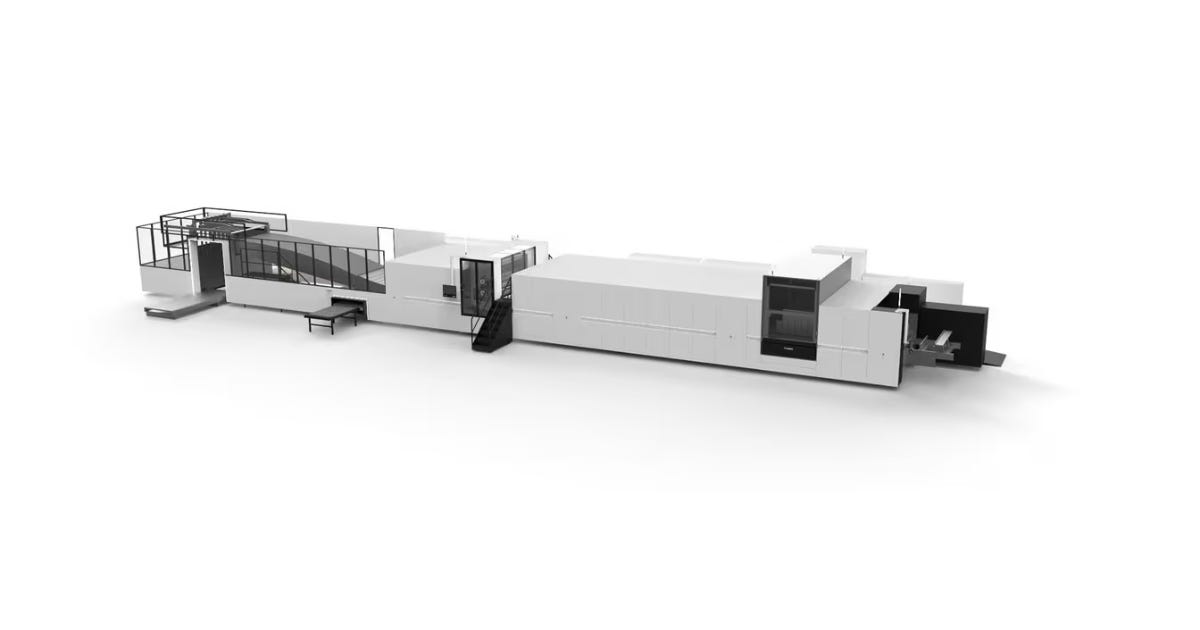

Canon announces corrPRESS iB17 for industrial corrugated

Epson launches S3200-S1 printhead for strong solvents

Kongsberg debuts Smart Material Handler (modular, retrofit)

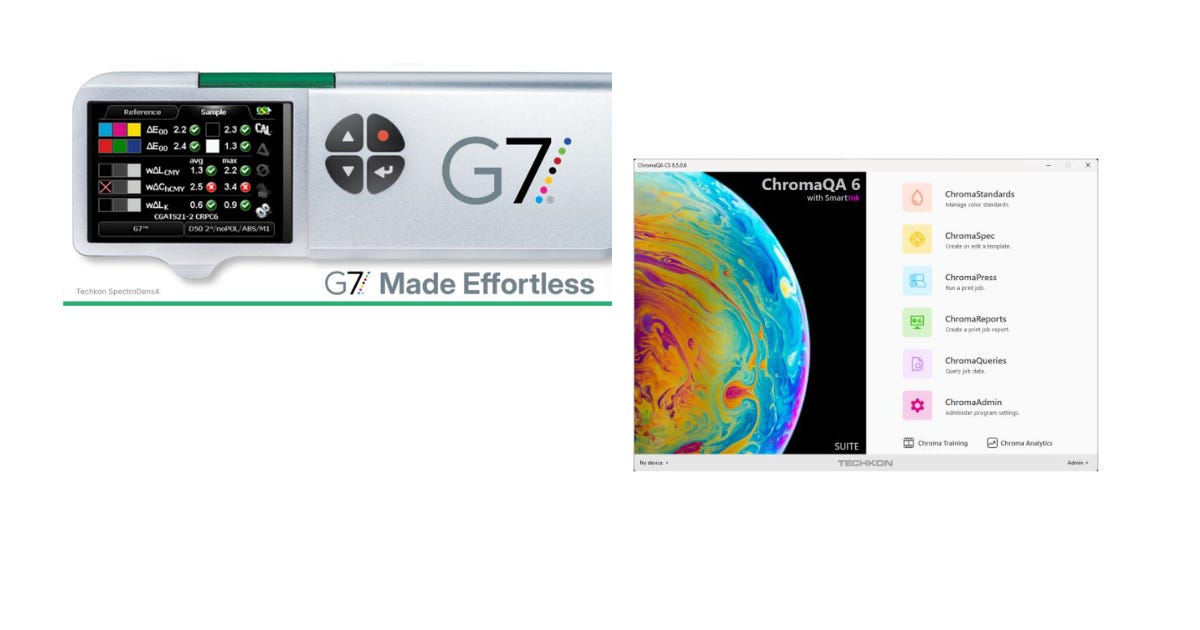

Techkon: G7/G7+ Exchange (sold out) + ChromaQA 6.5 updates

DuPont brings Artistri® inks + Tyvek® solutions to PRINTING United

📰 Top 5 Headlines This Week

Canon corrPRESS iB17 targets industrial-scale corrugated

Summary:

Canon announced the corrPRESS iB17, a next-gen inkjet press for corrugated packaging, printing up to 8,000 m²/hour with water-based inks and primer for indirect food contact. Positioned for short- to mid-run productivity with high automation.

Key takeaways:

Offset-like quality onto corrugated up to 1.7 m wide

High throughput and reduced operator requirements

Part of Canon’s push into labels & packaging

Why It Matters:

Corrugated is a growth engine; a high-speed, water-based platform with food-contact considerations opens doors for converters and display shops eyeing packaging.

Epson S3200-S1 head adds strong-solvent capability

Summary:

Epson introduced the PrecisionCore S3200-S1, a wide, high-resolution printhead compatible with strong solvents, aimed at industrial mass production (beyond graphics, too). Epson calls out applications from advanced manufacturing to emerging sectors.

Key takeaways:

Strong-solvent compatibility expands ink options and substrates

Wide print width + high resolution for productivity and precision

Signals more inkjet in industrial processes (not just signage)

Why It Matters:

For OEMs/integrators—and PSPs partnering with them—this broadens what inkjet can do in demanding environments.

Kongsberg’s Smart Material Handler (SMH) cuts idle time

Summary:

Kongsberg PCS launched SMH, a modular sheet-handling add-on for sign/display, folding carton, and corrugated cutting—compatible across C-series and Ultimate tables and available as a retrofit. Goal: reduce operator load and improve production flow.

Key takeaways:

Guides material flow between cuts; shortens changeover/idle

Scales automation without replacing the core table

Retrofit path makes the ROI easier to justify

Why It Matters:

Finishing bottlenecks kill margins. A modular handler that fits existing beds is a pragmatic speed boost.

Techkon anchors color with G7 Exchange + ChromaQA 6.5

Summary:

The Alliance’s inaugural G7/G7+ Exchange is sold out, with Techkon USA as a sponsor, underscoring rising demand for practical color standards. Techkon also brings ChromaQA 6.5 with SmartINK AI enhancements and GMG OpenColor compatibility.

Key takeaways:

Community momentum around measurable, shared color language (G7/G7+)

Faster ink toning and simplified colorant sets in ChromaQA 6.5

Tighter links to upstream proofing (GMG)

Why It Matters:

Standardized color + quicker corrections mean fewer reruns and faster approvals—vital for brands and PSPs juggling mixed processes.

DuPont brings Artistri® + Tyvek® under one roof at PU 2025

Summary:

DuPont will showcase Artistri® digital inks alongside Tyvek® media at PRINTING United 2025 (Booth #4367)—a joint presence aimed at end-to-end application demos across graphics and textile.

Key takeaways:

Portfolio storytelling: ink + substrate performance together

Signals continued push in textiles and durable graphics

Useful booth for application-level testing and spec questions

Why It Matters:

Seeing inks and media paired accelerates decision-making and reduces trial cycles—handy when planning Q4/Q1 rollouts.

🎯 This Week’s Strategic Takeaway

Pair throughput upgrades (corrugated or cutting automation) with color discipline and ink/media validation. The margin stack in 2026 looks like: faster finishing → fewer color do-overs → ink/substrate combos you trust.

❌ This Week’s Noise

“One color system fits all.” Reality: house standards matter, but client portfolios still demand G7/G7+ literacy and toolchains that translate between ecosystems. Pick a standard, then map the bridges you need.

📅 What’s Coming Up

🗓️ PRINTING United Expo 2025 – Oct 22–24 | Orlando, FL

Expect live looks at Canon’s packaging push, DuPont ink/media pairings, Techkon’s color workflows, and more automation around cutting/handling. Plan time for color audits and application tests—not just speed tours.

🧠 Smarter Every Week

Before a multi-board POP run, run a 60-second color triage: verify G7 target on one hero board, confirm ink toning recipe in your QC app, and print a trim-waste wedge after lunch. Afternoon drift is where many reprints are born.

Thanks for reading this week’s Wide Format Brief.

Keep testing new tools, fine-tuning workflows, and exploring smarter ways to add value—those small adjustments now set you up for a stronger Q4.