Your Weekly Large Format Print Briefing — Week 1, 2026

Your weekly 5-minute intelligence briefing for large format print professionals

Week 1 reopened after the Christmas and New Year break with a familiar signal: progress kept coming from simplification and proof—not flashy platform resets. AI showed up where it actually helped (prepress time), sustainability got measured by third parties, and textile workflows kept moving toward fewer steps and fewer failure points.

📢 This Week in Wide Format Brief

Xanté released iQueue 18 with AI imaging tools embedded in its PDF workflow platform.

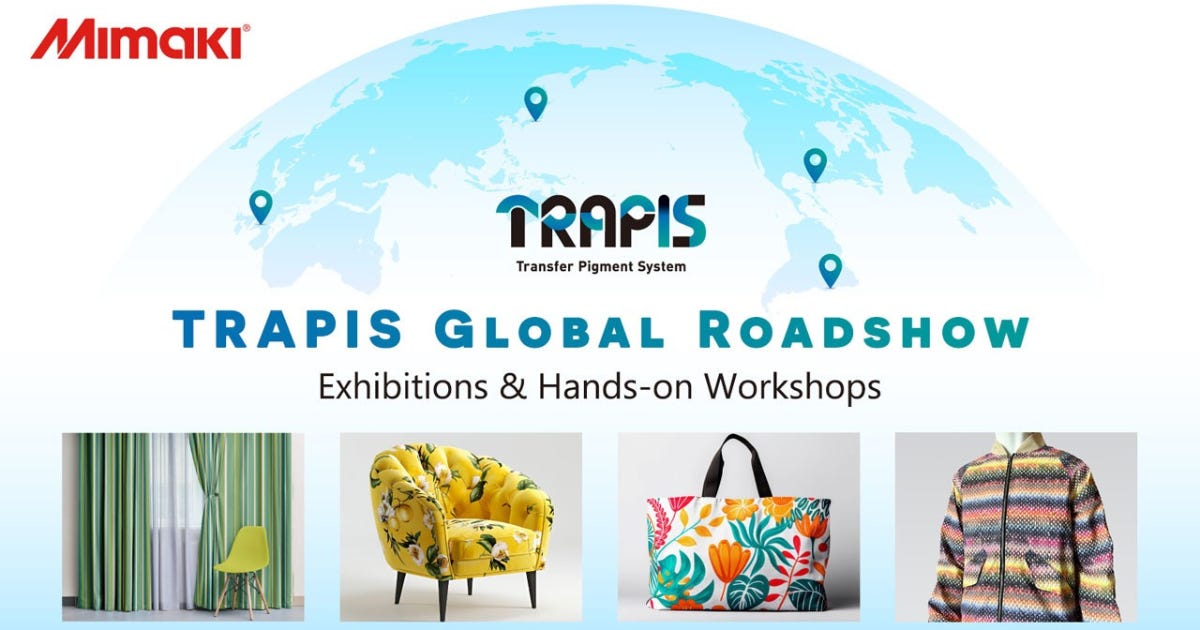

Mimaki promoted TRAPIS as a “anyone can do it” textile system through a global demo program.

INX International earned an EcoVadis Silver sustainability rating and tied it to supplier governance and reporting improvements.

Digidelta received FESPA UK Waste Accreditation Champions Recognition for waste and recycling standards.

Drytac published a 2025 customer innovation recap highlighting real application work using its materials.

📰 Top 5 Headlines This Week

Xanté Put AI Tools Directly Into Its iQueue PDF Workflow (iQueue 18)

Summary:

Xanté announced the release of iQueue 18 Workflow and said it integrated AI image upscaling, AI image generation, and AI image editing directly into the iQueue platform for use across Xanté print systems.

Industry takeaways:

Prepress time looked like the real target: upscaling and quick edits addressed the “file cleanup tax” that quietly ate margin.

Control risk increased: AI image generation and edits still needed operator standards (approval steps, customer sign-off, repeatability checks).

Workflow positioning mattered more than novelty: embedding tools inside the queue reduced context switching, which was where shops typically lost hours.

Why It Matters:

Wide format rarely lost margin at the printer—it lost it before the RIP, in the messy handoffs between “good enough art” and “print-ready file.” Tools like this only helped if they reduced touchpoints and kept accountability clear: who approved the change, what changed, and whether the result stayed consistent across reorders.

Mimaki Pushed TRAPIS as Textile Printing That Reduced Steps, Labor, and Water

Summary:

Mimaki positioned TRAPIS as an easy-to-operate textile printing system and said it significantly reduced process labor and water use versus conventional methods, while supporting small-lot production across a variety of fibers in a compact space.

Industry takeaways:

Textile scaled when it became predictable: reducing chemistry/process complexity typically lowered training burden and quoting variability.

Small-lot + mixed fibers pointed at diversified revenue (soft signage, décor, short runs) but only if finishing capacity kept up.

“Anyone can do it” needed validation: operators still had to manage color expectation, fabric behavior, and post-processing consistency.

Why It Matters:

Textile opportunity was real, but many shops got burned by the hidden complexity—fabric variables, process steps, and rework. A system that reduced steps and water usage could be meaningful if it made repeat jobs easier to match and made onboarding less dependent on one “textile guru” in the building.

INX Earned EcoVadis Silver—A Signal That Supplier Qualification Got Stricter

Summary:

INX International reported it earned an EcoVadis Silver Medal rating, placing it among the top 15% assessed, and linked the result to improvements in ESG governance, environmental performance, and reporting systems.

Industry takeaways:

Procurement reality: EcoVadis scores increasingly influenced approved vendor lists—especially for brand-driven work.

Environmental scoring jumped (INX cited improvement in the environmental category and a top-tier ranking for environmental systems), which mattered for customers asking for proof, not promises.

Ink supplier ESG affected more than packaging: wide format buyers faced the same “show me the documentation” pressure in bids and renewals.

Why It Matters:

Shops increasingly got dragged into customer ESG requirements whether they liked it or not. When suppliers carried recognized third-party ratings, it reduced friction during audits and proposals—less scrambling for documentation, fewer delays, and cleaner answers when a brand asked, “What’s your supply chain doing about this?”

Digidelta Earned FESPA UK Waste Accreditation Champion Recognition

Summary:

Digidelta announced it received the FESPA UK Waste Accreditation Champions Recognition Award 2025, tied to a voluntary scheme evaluating waste generation, outputs, and disposal practices for the print, signage, and graphics industries.

Industry takeaways:

Waste handling stayed a differentiator: end-of-campaign vinyl and graphics were a pain point customers increasingly asked about.

Accreditation carried more weight than marketing: third-party criteria helped separate operational practice from “green language.”

UK/Europe influence often spread: once a standard became common in one market, national buyers started referencing it elsewhere.

Why It Matters:

Sustainability talk stayed cheap until disposal became visible and regulated by customer expectations. Recognition programs mattered when they pushed shops toward documented processes—segregation, tracking, vendor partners, and proof—because that was what customers asked for when a contract renewal hit.

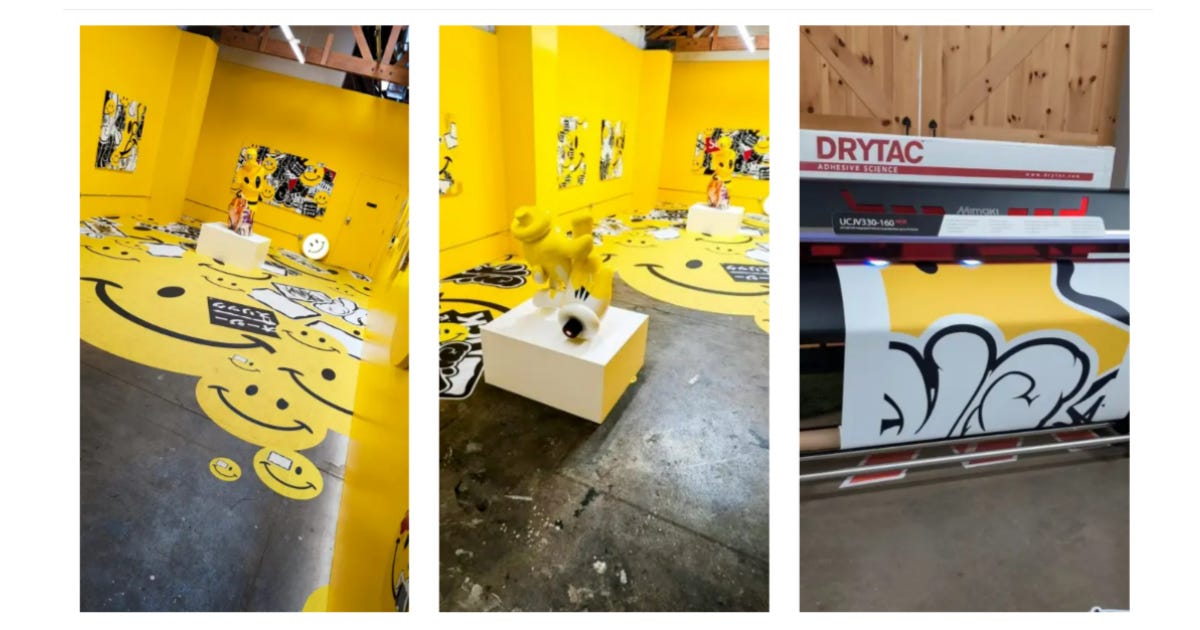

Drytac’s “Best of 2025” Recap Highlighted Where Material Choice Still Won Jobs

Summary:

Drytac published a year-end recap showcasing customer work and emphasized that customer feedback and collaboration influenced product development and real-world applications across regions.

Industry takeaways:

Applications beat specs: many profitable wide format jobs were won on install performance, removability, and surface compatibility—not printer features.

Customer-led development hinted at where demand stayed strong: short-turn décor, event installs, retail refresh cycles.

Material strategy remained a shop advantage: standardizing a few proven films/adhesives often reduced rework more than chasing new hardware.

Why It Matters:

After the holiday break, shops typically returned to the same reality: throughput and install quality decided margins. A strong materials playbook—what stuck, what removed cleanly, what stayed stable—kept jobs repeatable and reduced “mystery failures” that turned a profitable install into an expensive redo.

🎯 This Week’s Strategic Takeaway

Week 1 closed with a clear pattern: the most valuable moves reduced variability—whether that came from simpler textile processes, third-party sustainability proof, or AI tools aimed at cutting prepress touchpoints.

❌ This Week’s Noise

“AI creativity” messaging offered inspiration, but it lacked the operational controls shops needed: standards, approval checkpoints, and measurable reductions in rework time. Without that, it stayed a demo—not a workflow improvement.

📅 What’s Coming Up

📅 C!Print Madrid 2026 — 13–15 January 2026 | IFEMA Madrid

A strong bellwether event for visual communication, print, finishing, and personalization in Southern Europe—useful for reading where buyer demand was heading early in the year. C!Print Madrid - website

📅 Heimtextil 2026 — 13–16 January 2026 | Frankfurt am Main

The first major 2026 checkpoint for textile demand, materials direction, and production trends tied to décor and interior applications.

🧠 Smarter Every Week

Before restarting full production after the holidays, lock a single reference job and run it end-to-end: nozzle check, media/profile validation, finishing calibration, and a quick install/adhesion sanity check. Comparing that same job weekly exposed drift before customers did.

Thanks for tuning into this week’s Wide Format Brief.

As the first issue after Christmas and New Year, this one focused on the practical signals worth bringing into January planning. Until next time—keep printing.